Nanofibrillated cellulose (NFC), is an engineered 1D nanomaterial that can be produced from abundantly found natural cellulose sources. Having a very high specific surface area (above 500 m2/g), thixotropic (shear thinning) behavior and reactive structural side groups (cellulosic hydroxyl groups) make NFC a perfect binding material for functional coatings. Cylindrical fiber geometry in NFC facilitates constructing stable ultrahydrophobic and omniphobic coatings on textiles [1]. This result in formation of hierarchical coatings (from submicrometer to nanometer range) at a broad range of length scales.

NFC promotes adhesion of the functional material to fabric surface by acting as a binder, ensuring higher fixation and retention. Based on this concept, our research team has studied two major applications of NFC in textiles,

1). Properties of NFC functional coatings 2). NFC based novel environmentally sound textile dyeing technique for the cotton industry.

We have investigated the effectiveness of NFC as a binder and properties of NFC coatings in various textile applications.

Using NFC as a carrier for textile dyes led to developing a novel dyeing technique. For the past seven years, the UGA-team has developed NFC based sustainable and industrially applicable textile dyeing technology which promises more than 80% dye fixation and excellent dye performance [2]. Furthermore, the life cycle analysis of this new dyeing technique also shows this process utilizes less energy and has a lower carbon footprint compared to the conventional dyeing method. Most importantly, this technology consumes ten times lower quantity of water and dye auxiliaries compared to the exhaust-dyeing method. We are currently in the phase of optimizing this research, concerning macro and micro business aspect of the current textile industry. Based on the recent research updates, we have achieved following milestones in NFC based dyeing technology.

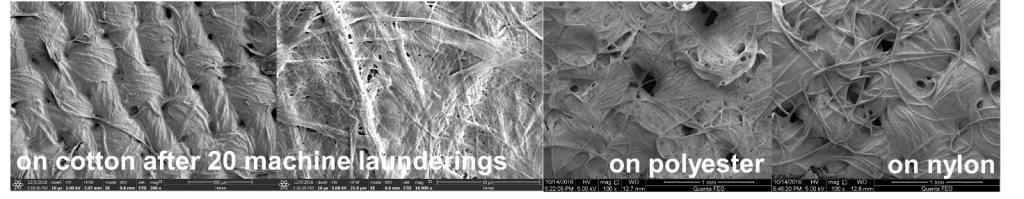

- Dyeing of diversify textiles, such as cotton, nylon, polyester and blended textiles.

- Optimization for batch or continuous dyeing process using different deposition methods such as knife-coating, spraying, and printing.

- Compatibility of NFC with different dyes such as reactive, indigo, sulfur and vat dyes.

- Dyeing with monochromatic reactive dye color systems (red, blue, black and yellow) and trichromatic color shades (e.g. brown shade).

As per our new findings, dye performances (fixation, colorfastness, and retention) of NFC dyeing can be further enhanced from chemical crosslinking post-treatments that increase the adhesion between NFC and fabric surfaces.

We have studies in progress to elevate fabric comfort and texture (such as stiffness, air permeability, and fire-retardance) to meet consumer needs.

EFERENCES

[1]. I. Usov, G. Nyström, J. Adamcik, S. Handschin, C. Schütz, A. Fall, L. Bergström and R. Mezzenga, “Understanding nanocellulose chirality and structure–properties relationship at the single fibril level,” Nature Communications, no. 7564, 2015.

[2]. Kim, Y., et al., “Environmentally sound textile dyeing technology with nanofibrillated cellulose”. Green Chemistry, 19(17): p. 4031-4035, 2017.

ACKNOWLEDGMENT

Cotton Incorporated, The NATO Science for Peace and Security Program, Walmart Manufacturing Innovation Fund, and The Elsevier Foundation.